Hydraulic System Enhances Press Performance

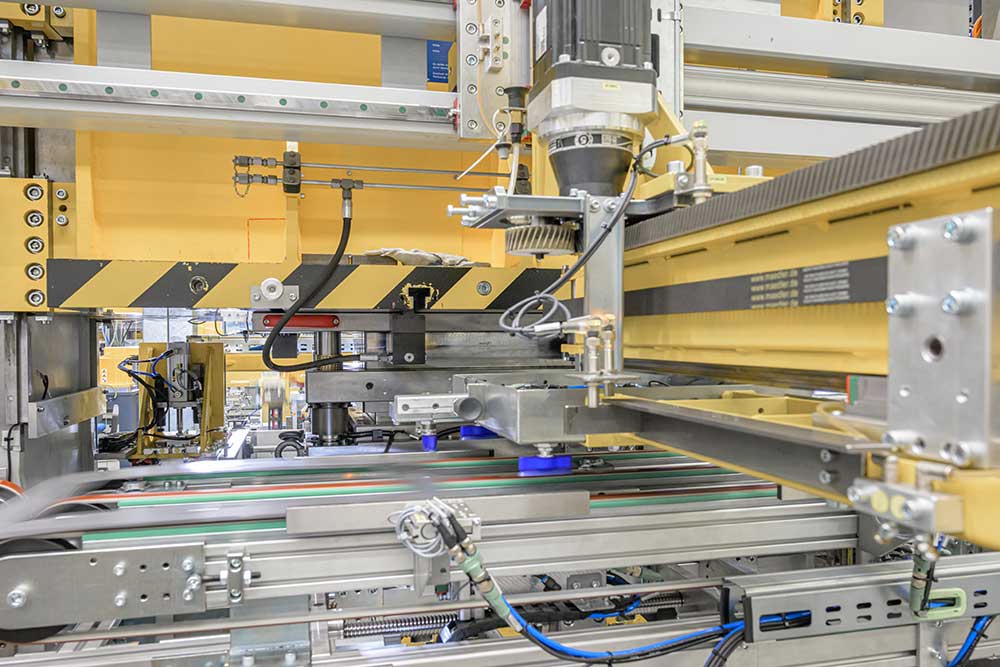

A modular industrial hydraulic system, from Bosch Rexroth, plays a key role in future-proofing a metal-forming press.

How can a press series in the medium-performance class be designed and produced to meet the reliability, energy, and sound demands of today’s manufacturers? Machine and system manufacturer Dieffenbacher, Windsor, Ontario (dna-manufacturing.com) has found an answer using state-of-the-art industrial hydraulics from Bosch Rexroth, (boschrexroth.com). Dieffenbacher serves small businesses such as craft operations and workshops, as well as industrial companies that are looking for an economical solution for forming metal and composite components.

“We wanted to build a future-proof, 1,000- to 10,000-kN press from standard modules that can be customized in terms of force, installation space, table, and ram size,” explained Georg Obermaier, Head of Business Unit Forming for the new TailoredPress concept. “At the same time, we placed high demands on energy efficiency. We found both aspects were fulfilled by our system partner Bosch Rexroth, with whom we jointly designed a modular drive concept that they were ultimately able to produce for us.”

Sustainable Forming Technology

Dieffenbacher manufactures pressing and complete production systems for the wood-based material, forming, and recycling industries. In addition, the family-run company, headquartered in Eppingen, Germany, offers a wide range of advanced solutions for sustainable energy efforts. As part of its sustainability strategy, Dieffenbacher has committed itself to reducing its own green-house gases by 50% by 2030. An important secondary goal is that the machines they build be as energy efficient as possible. In line with the overall concept, the drive module for the TailoredPress needed to be constructed, as much as possible, with standard components.

The modular drive concept means that Dieffenbacher can easily offer the TailoredPress in different performance and speed classes. For example, a 500-tonne version can simply be upgraded to a speed version with active high-speed parallel holding for precise component thicknesses and higher component quality by using a different pump size. The entire range of operational and process demand is covered by the Bosch Rexroth pump program, which streamlines the processes over the life cycle from engineering to warehousing and service. Other versions, with draw cushions, can also be quickly realized using the modular system.

The Dieffenbacher TailoredPress offers digitized controls, potential energy savings of 70%, and a quiet 70-dbA noise emission.

Power On Demand

For the main drive, the modular drive concept uses a type-A4VSO axial piston variable pump in various sizes, with a digital HS5 control unit. It uses the IH04 press module with standardized safety concept and EG-type examination certificate for performance level e category 4, in line with the requirements of DIN EN ISO 16092-3 and DIN EN 289. A functionally equipped multi-station manifold and a motor-pump unit with the A10VSO axial piston variable pump are used for the control and water-cooled filter circuit. The complete package also includes a speed-controlled hydraulic power unit, suitable for the respective press design.

The electro-hydraulic drive concept generates volume flows in line with demand, through either the swivel angle or the motor speed, allowing the pump to operate at 1.5 times the power, if required. The digital control adjusts the volume flow precisely to the individual process points. If no production is required, the pumps are switched off so that the TailoredPress consumes almost no energy when idle.

70% Energy Savings

Compared to a conventional drive with a constant speed, the optimally controlled electro-hydraulics save approximately 50% of the energy previously required. Combined with an adaptive battery control, the energy-saving potential increases to 70%. The directly driven TailoredPress automatically adjusts the charging pressure of the hydraulic accumulator to the upcoming forming process. From the operating personnel perspective, nothing changes. Forces, travel and ram parameters are set as usual and respective speeds are calculated in the background. The press operates at a quiet 70 dbA.

The drive concept is compatible with the Dieffenbacher EVORIS digitalization platform, which makes possible remote maintenance, condition monitoring, and/or data-based analyses for process improvements or predictive maintenance. “Standby mode for downtimes alone usually saves 20% in electricity costs and indirect CO2 emissions,” explained Georg Obermeier.

From Obermeier’s perspective, the latest Rexroth project is a complete success. “Thanks to the new drive concept, we can offer a future-proof press concept with attractive value and a fast return on investment. The collaboration was committed and solution-oriented, from engineering and commissioning to production, support, and spare parts supply.”

EP Editorial Staff | August 22, 2024

For more information, visit boschrexroth.com.

The post "Hydraulic System Enhances Press Performance" appeared first on Efficient Plant