Maintenance Challenges In Healthcare: Turning The Page

Evolution is underway as the industry embraces a new chapter. Both today’s aging and youthful workforce and fast-paced culture are colliding with technological advancements. What are the results of a shifting demographic mixed with higher tech? How is that impacting maintenance? How does that impact a facility, and specifically healthcare?

Technology evolves continuously. The world was much different than 15 years ago, and this was true 15 years before that point. Hand drawings evolved into CAD, CAD evolved into Revit, and now tools like BlueBeam and Matterport are becoming increasingly common. Equipment controls have advanced, chillers and boilers are more efficient, and research into refrigerants and electrification is reshaping infrastructure. The next decade promises even more change, much of it still unknown.

Instead of trying to predict every technological shift, it’s crucial to consider how today’s workforce and cultural changes are impacting facility maintenance.

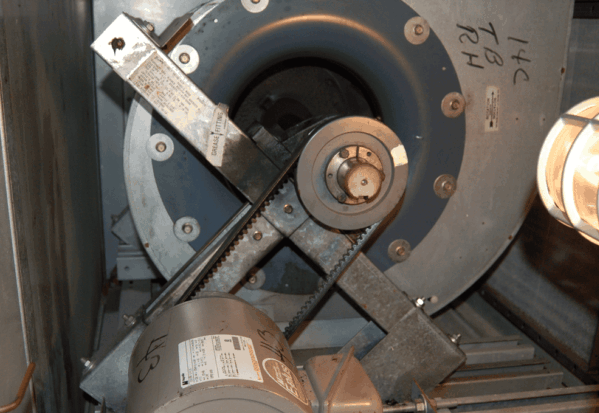

Keep The Engine Running

When it comes to maintenance, a building’s lifespan far outlasts most of its equipment. Especially in aging hospitals, it’s common to find systems that are more than 20, 30, or even 40 years old still in operation. Some 70-year-old systems run better than 15-year-old ones because of solid maintenance practices. Maintenance is the oil that keeps the engine running. Without it, systems fail, and in hospitals, that failure can impact lives.

The core purpose of a hospital is to save lives, and design decisions should reflect that. However, short-term costs are always an important factor. Systems designed for longevity cost more upfront, leading to budget-friendly decisions that offer quick fixes instead of lasting solutions. Fan coil units may be added while aging air handlers are ignored, or cheaper DX systems are selected over robust chilled water plants.

Sometimes, it feels easier to settle for “good enough,” especially when a key decision-maker is nearing retirement. But both Owners and Consultants need to stay vigilant by identifying equipment needs, communicating risks clearly, and helping facility managers justify necessary upgrades. This sounds simple and obvious, but in today’s fast-paced culture, it takes a focused team working together to keep this at the forefront. Today’s maintenance teams are already paying for yesterday’s decisions and facing an ever-growing list of problems.

Programming Tomorrow

Design software has evolved from AutoCAD to Revit and beyond, and AI is poised to influence these tools further. These programs promise efficiency, but they also bring complexity, requiring users to spend time learning software rather than focusing on practical, maintainable designs.

While tools like Revit improve visual planning and clash detection, they can also give a false sense of confidence that maintenance access and other practical needs are fully addressed. AI will intrinsically have the same challenge of false security, if not more so. A well-designed system still requires the human element. It must consider the maintenance worker who will live with the design long after it’s built.

Adding to this challenge, there’s been a cultural shift toward convenience. More equipment than ever is made to be “throw-away”, and the tenured skilled laborer with the know-how to fix equipment is dwindling. Budget constraints and staff shortages are forcing facilities to do more with fewer people. Hospitals, in particular, must continue 24/7 operations despite these growing limitations. These are factors that must be considered during project design.

Generation Gap

The workforce is going through a sizable transition. The “silver tsunami” is taking hold. Baby Boomers are retiring, and Gen-X is too small to replace them alone. Millennials have now become the largest share of the workforce, with Gen-Z close behind. These generational shifts bring not only demographic change but also differences in skills and values.

Maintenance personnel and skilled trades workers are feeling this shift. Long-tenured employees are retiring. That knowledge isn’t easy to replace. Hospitals already operate with smaller crews than a decade ago, and hiring replacements is becoming harder.

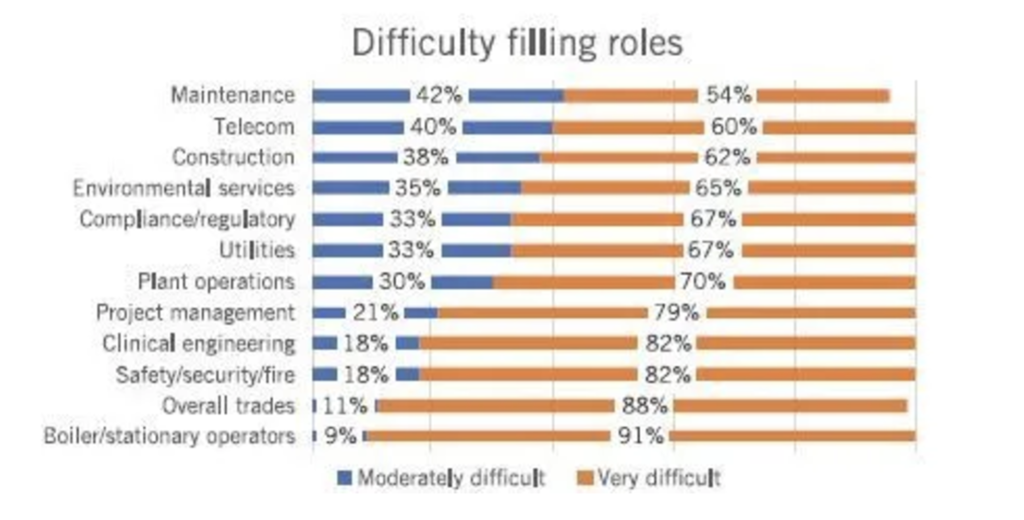

A 2023 ASHE membership survey reported that 54% of facility leaders find it “Very Difficult” to fill general maintenance roles, and 88% say the same for trades positions. This troubling trend has continued through 2025. Furthermore, approximately a third of the current workforce expects to retire in the next five years. This is a seismic shift in both the knowledge base and generational approach to problem-solving.

(Credit: Lisa Walt, Ph.D. “Filling in-demand facility roles and positions”, HFM October 2024 issue)

Fill The Gap

Technology can help fill the gaps. Energy management programs and building analytics infused with AI may help “learn” buildings and identify troublesome areas that need focus. These programs could help predict issues before they arise, helping to curb the “just keeping up with the fire of the day”. While these programs can help diagnose, they still do not do the physical work (yet anyway). Changing filters, replacing belts, swapping motors, etc., are still physical limitations that require manpower.

Furthermore, the firefighting model common in today’s culture is not a sustainable one. When someone cannot see beyond today’s fire, they certainly can’t see or plan for the bigger challenge on its way tomorrow. That may be planning for the replacement of AHUs serving critical areas that have been patched together for the past decade plus, getting the chemical treatment program under control before boilers start failing, or coming up with a plan to upgrade the controls system to the next generation before personnel can no longer find parts on the secondhand market. The overburdened maintenance worker may know these things need to happen, but finds themselves too busy to provide the necessary input for proper planning. All these systems directly impact critical functions of hospitals, and they must remain seamlessly operational for the facility to serve the mission of saving lives.

With all the uncertainty of change, there is reason for optimism. Taking on big challenges is nothing new, and there is no doubt the industry will rise to the occasion. Much good can and will be realized. However, these challenges are a reality to be addressed, and peripheral things like the maintenance crews and lifeblood of the facility must be kept in focus as programs continue to evolve and “optimize”.

By Mark Wehmeyer, P.E., ASHRAE HFDP, McClure Engineering

Mark Wehmeyer, P.E., ASHRAE HFDP, is a Mechanical Engineer at McClure Engineering, a mechanical and electrical consulting engineering firm dedicated to the development of innovative solutions to unique engineering problems.