Augmenta AI Helps Organize Electrical Work on School Jobs

Electrical contractors are usually the last trade in to the project design phase, and by then, are competing with mechanical and plumbing systems for space in crowded pathways. Endless change orders and delayed coordination meetings can also further threaten installation timelines for electrical systems.

With all of this in mind, electrical contractor C&R Electric decided to try something different for an upgrade of Mt. Hope Elementary School in Lansing, Mich. The project design “had a Revit model and it was fairly simple to start with, being K-12. It had a lot of pipe in it, and a simple corridor system,” says Kyle Sponseller, president of C&R Electric, Shepherd, Mich. “It was a good candidate to test an artificial intelligence system on.”

The company used the AI engine in Augmenta software that can automate detailed design and routing of electrical systems—generating designs from initial prompts such as square footage and volumetric dimensions. The tool can generate designs in minutes rather than days, with relatively few corrections needed.

Sponseller says the firm was able to cut 100 hours from the design process, the equivalent of an entire month’s worth of “prefabrication getting-drawings-ready time” for the Mt. Hope project. Augmenta’s AI was also able to help C&R and Lansing contractor The Christman Co. use less conduit and fewer fittings based on the more detailed drawings with exact quantities.

“We are always seeking innovative methods to deliver high-quality, efficient buildings for the communities we serve, and with Augmenta’s help, this school [project]is a shining example of that commitment,” says Andrew Dobbs, the contractor’s project manager.

Augmenta CEO Francesco Iorio worked with the team to get the most out of his company’s AI engine, including how to ask the right queries and to take best advantage of prefabrication opportunities.

“It was 50% faster design and 15% savings in materials, too,” Iorio says. “Not only did these folks not have to pay for that material, but they also did not have to bring it to the site, bend it, cut it, then toss half of it away after that process.”

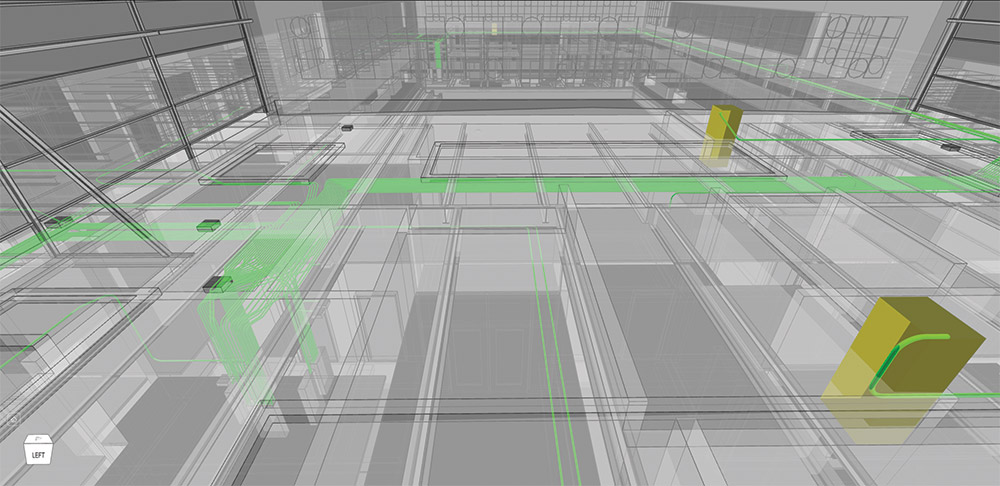

AI took the project Revit model to create usable drawings for the electrical subcontractor.

Render courtesy C&R Electric

C&R has more experience under its belt with Augmenta now. Its second project using the AI tool, Willow Elementary, also in the Lansing School District, had even better results. The company benefitted from an additional 50% reduction in design time and reduced an estimated 400 hours of manual drafting into just 80 hours of work. It also trimmed material waste by 25%—a considerable improvement from the Mt. Hope project, all from refining and improving use of Augmenta’s generative AI design tool.

According to Sponseller, time savings like this can help electrical trades who often may join a project after mechanical and plumbing trades have taken up most of the space in the design needed for electrical conduits. “A lot of times you start in a meeting on a BIM model and the mechanical [firm] say it is 90% done, but you just got the model yesterday,” Sponseller says. “The same thing with plumbing, so now this is my opportunity to get a model, dump it all into Augmenta and say ‘yeah, I’m 90% done too,’” he explains.

The prefabrication assistance alone made Augmenta worth it, Sponseller adds. “[Mt. Hope] was fun, because it was a good model from the architect, and we used Augmenta, and used Allied BIM to run its results through our prefabrication machines,” he says. “We actually took the Augmenta product, cleaned it up and then we pushed it through [computer-controlled] equipment in our shop, and actually built it and shipped it to the site.”

The post "Augmenta AI Helps Organize Electrical Work on School Jobs" appeared first on Consulting-Specifying Engineer