Filling the Gaps: Robots Close the Loop for Digital Twins

The construction industry has invested heavily in digital tools for more than a decade, yet walk any job site and the same problems persist. We’ve spent billions on BIM, digital twins, and visualization software, but still face rework, poor installation quality, and crews checking measurements by hand. Look around and you’ll find tape measures, chalk lines, and conflicting benchmarks across the job site. It’s a reminder that our digital investment still stops at the trailer door.

The problem is simple and expensive. We digitize the design but not the work. We build detailed models, but the way we build hasn’t progressed at the same pace. Until construction digitizes its physical workflows, tools, and verification, digital twins will keep falling short of their promise.

A Broken Thread: Design vs. Production

Mike Tyson once said, “Everyone has a plan until you get punched in the face.” In construction, the model is the plan, and the job site is the punch.

You pour concrete and the column lines are slightly off. You start hanging pipe and clash with the existing structure. Crews follow the plan but make field adjustments to accommodate what was built before them. We have digital intent, but our field execution remains analog. The digital twin, which should reflect a living process, turns into a static file that loses value as soon as real work begins.

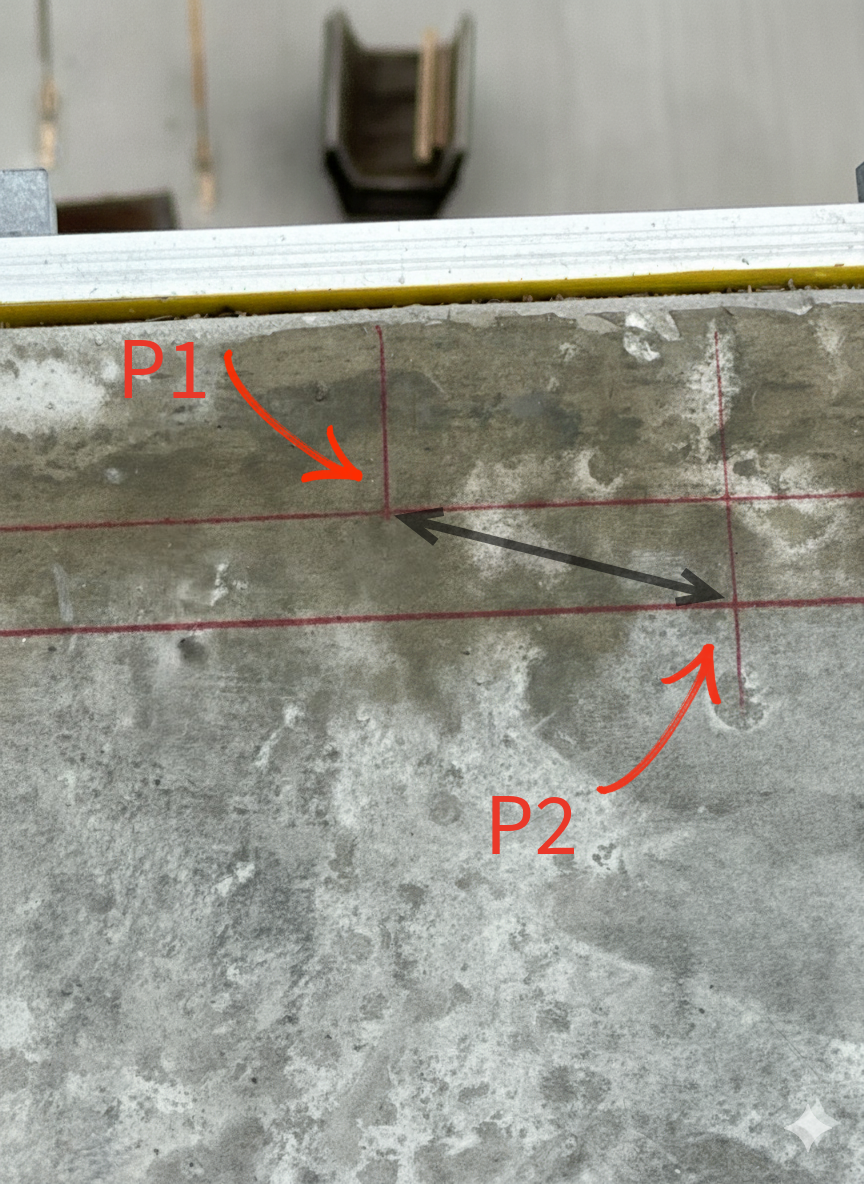

This disconnect costs real money. On one façade project I worked on, two subcontractors shared responsibility for adjoining panel sections installed in an alternating sequence. Both used different layout teams and slightly different assumptions. One crew adjusted its spacing in the field to accommodate slab shifts, while the other followed the layout drawings exactly. Both meant well, but those small adjustments became major errors. Once their work was compared, the deviations exceeded what could be corrected in the field. A quarter-inch allowable tolerance became inches of mismatch across the floor line.

This also raises a larger question: what happens when that same façade is adjusted for slab conditions, but interior partitions have already begun? If wall-to-mullion connections have tighter tolerances than the concrete, the change creates rework. If every trade were tied to the same live model that updated as-built conditions in real time, those problems would never reach installation.

We Are Digitizing Paper, Not Processes

These are not isolated mistakes–they show how disconnected digital coordination is from field execution. Data flow stops at the site. Without structured feedback, we rely on interpretation and memory. Even the best digital twin cannot fix what it cannot see.

As Hamzah Shanbari said, the industry keeps “digitizing paper, not process.” Replacing blueprints with PDFs is not a transformation; it’s a translation. The software changed, but the work did not.

From Projects to Production System

The real obstacle is not technology–it’s how we think about projects. Construction treats every job as a one-off, while industries like manufacturing or energy treat theirs as production systems. Todd Zabelle wrote, “Until we recognize projects as production systems and use operations science to drive project results, we are doomed to failure.” Without visibility into production, there is no feedback loop, no correction, and no real improvement.”

Manufacturing knows the cost of every delay because it measures performance as a single continuous system. Construction calls itself too complex for that, but the truth is more straightforward—manufacturing manages its process; construction manages paperwork.

To manage construction as a measurable process, we need verifiable, structured data coming back from the field. Right now, that feedback depends on people filling out daily reports, checklists, or photo logs by hand. Some apps make this easier, but the information is still subjective—it’s only as reliable as the person entering it. Without objective data capture, there is no reliable feedback loop.

In manufacturing, sensors and machine logs feed data directly to control systems, giving managers a live view of throughput, quality, and downtime. Some processes still involve human quality review, but they are part of a structured system. Construction has no such mechanism. Each contractor acts as an isolated station in the process, largely due to risk mitigation concerns. Contract language encourages separation and self-protection. There are few shared standards for verification, so feedback remains fragmented.

Imagine if each workstation on a manufacturing line were an independent company, each with its own data, tools, and risk profile. That is how construction operates today. The system works, but only because it must. The real opportunity lies in building that same structure through shared data, not control.

Market Pressures Demanding Change

Two forces are making this change unavoidable. The first is labor. For decades, experienced tradespeople made quiet field fixes when drawings conflicted or conditions changed. That knowledge base is disappearing as veterans retire. Younger workers understand the software but lack the experience to catch small errors before they grow. Without data-driven verification, those errors now travel further and cost more to fix.

The second is precision. The growth of hypercritical infrastructure projects—data centers, battery facilities, and clean rooms—is driving owners to demand higher levels of detail. Many now require LOD500 deliverables as standard. But collecting, processing, and organizing that much verified as-built information can cost nearly as much as building the project itself. LOD500 provides the framework for true digital twins, but the cost and overhead make it impractical for widespread use.

Bridging the Gap Between Data and Work

3D scanners and robotic total stations are a good starting point, but they have limits. Full-site scans can cost tens to hundreds of thousands of dollars per project and still require manual setup and interpretation. Point clouds often return unstructured and difficult-to-verify data. Ground-penetrating radar faces the same problem–it detects utilities and voids, but the data is delivered as flat anomaly maps instead of geometric models.

Most firms avoid interpretation because of liability risks. Even when the data is collected, it arrives incomplete. Occlusions, limited coverage, and time gaps between scans leave critical areas undocumented. It’s like a bad manager checking in occasionally to ask, “Is everything okay here?” while missing the thousands of changes in between.

Automation changes that by shifting data collection from periodic to continuous. Robots equipped with LiDAR, vision systems, and localization sensors collect data as they perform their work. Each hole drilled, bracket placed, or inspection completed adds directly to the shared as-built model. Instead of working around occlusions, the data is captured as those occlusions are being installed. The structure documents itself as it is enclosed.

Because the data is generated as the work happens, it includes geometry, context, and timing. This eliminates pauses, manual registration, and the heavy post-processing required by traditional scanning. Documentation becomes a byproduct of the work itself. Robotic data collection creates a continuous digital heartbeat for the project, similar to a manufacturing line, where deviations are caught early and accuracy improves over time.

With automated verification, owners can achieve LOD500 accuracy without the cost and documentation burden that previously made it unrealistic. Robots, sensors, and connected tools finally close the feedback loop that digital twins have always promised.

The Path Forward

The gap between model and reality will not close through more software. It will close through verified, continuous feedback from the field. Automation provides that connection, allowing every part of the project to measure itself in real time and produce data that is accountable and actionable. Instead of building a new digital twin at project completion, the twin builds itself as the job progresses.

Automation will not eliminate the need for skilled workers; it will elevate them by giving them data-backed decision-making power in real time. Automation replaces assumption with proof, turns verification into collaboration, and transforms construction’s static models into living systems.

The question is not whether construction can digitize further. It is whether we can afford not to.

Conley Oster is co‑founder and COO of Raise Robotics. With a background in structural engineering and extensive experience in crane and rigging operations on complex construction projects, he now leverages his field expertise to advance practical robotic automation in the industry.

The post "Filling the Gaps: Robots Close the Loop for Digital Twins" appeared first on Consulting-Specifying Engineer