Electrical Room Basics, Part 1

Frequently, people associate an electrical room with Article 110 of the National Electrical Code® (NEC®). More specifically, they associate it with section 110.26. But is that accurate? The answer would be “kind of”.

Section 110.26 deals with what it calls working space about electrical equipment, not electrical rooms. After all, these rooms are sometimes used for other mechanical equipment like furnaces or water heaters, which is why they are sometimes referred to as mechanical rooms. The one thing they are not is storage rooms.

The sections within 110.26 are specific to working spaces about electrical equipment that may or may not be within a room. Working space may be in a corridor, basement, exterior, or even a garage. However, the section that could be interpreted to require an electrical room is 110.27, which requires live parts be guarded against accidental contact. One of several methods to accomplish this is by placing electrical equipment in an electrical room or vault. Therefore, most architects design a separate electrical room, or mechanical room, for the main service equipment and mechanical equipment for the building, which is usually less expensive than an electrical vault. In most cases, the room is locked, which helps create a method of control to ensure only qualified persons have access to energized electrical equipment as outlined in 110.26(F).

Contained within the electrical room is the working space about the electrical equipment as described in the 2023 NEC, section 110.26(A). This space consists of several parameters, some of which are outlined below.

· Depth of Working Space is a measurement that considers nominal voltage to ground and if there are grounded parts or exposed live parts across from the equipment. This information lines up with the conditions outlined in Table 110.26(A)(1). To determine this measurement, one must select the condition that applies to the installation. Then measure from exposed parts (soon to be live) or from the face of the enclosure, if live parts are enclosed, extending out the front until the minimum distance within the table is achieved.

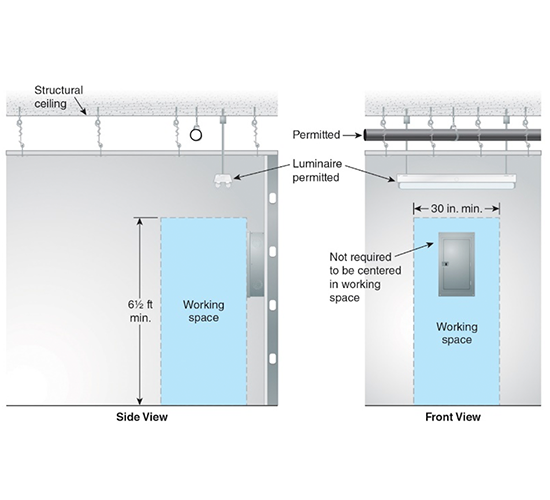

· Width of Working Space is a dimension derived from measuring the width across the front of the electrical equipment. This can be taken from center (15 inches in middle of equipment), from left side of equipment or from right side. No matter the amperage the maximum width will be equal to the width of the equipment but will not be less than 30 inches.

· Height of Working Space is measured from grade, floor, or platform to a height of 6.5 feet and is the width of the equipment or at least 30 inches and extends out to the depth of the working space. Other items such as luminaries or sprinkler pipes may be above this space, but not within it.

· Grade, Floor, or Working Platform requires the grade, floor or working platform to be kept clear and that the floor, grade, or working platform be as level and flat as practical for the entire depth and width of the working space for the applicable working space. This is largely because electrical equipment that requires servicing may be in different environments.

· Entrance to and Egress from Working Space requires at least one entrance of sufficient area to give access to and egress from the working space. Depending on the size of the equipment (see 110.26(C)(2)), the entrance and egress to/from the working space could be 24 inches wide by 6.5 feet high. Open equipment doors must not impede access to and egress from the required working space. If one or more equipment doors are open and access to and egress from the working space is reduced to less than 24 inches wide and 6.5 feet high, the access is considered impeded.

Most of us have seen electrical equipment located outside of the electrical room. Sometimes a panel is in a corridor of a school or back hall of a store or even outside. Panels located outside of a building may require other means to guard the live parts from accidental contact and to create a compliant working space. No matter where the electrical equipment that may require servicing is located, all of section 110.26 applies.

So, working space and section 110.26 must be accounted for by architects and design professionals in the overall layout and installation of electrical equipment to allow for safe access, operation, and maintenance of that equipment.

Stay tuned to NFPA Today for part two in this blog series titled Electrical Rooms, where we will explore the working space requirements for equipment over 1,000 volts, nominal.

Important Notice: Any opinion expressed in this column (blog, article) is the opinion of the author and does not necessarily represent the official position of NFPA or its Technical Committees. In addition, this piece is neither intended, nor should it be relied upon, to provide professional consultation or services.

The post "Electrical Room Basics, Part 1" appeared first on NFPA Today Blogs