Weathering The Storm: Roofing For Resilient Commercial Properties This Hurricane Season

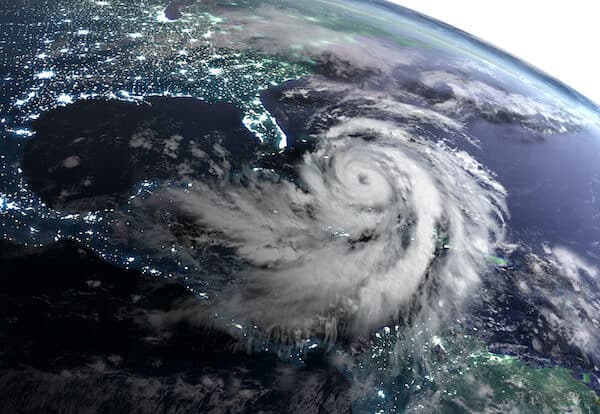

During the months of June through November, hurricane season poses significant risks to properties across coastal regions of the United States. In recent years, hurricanes such as Helene and Milton have caused extensive property damage, particularly in the Southeast. Harsh elements like heavy rain, high winds, and humidity pose serious threats to commercial properties, ranging from costly repairs to full roof replacements. As storms grow more frequent and intense, integrating resilient materials and systems into the design is no longer optional; it’s imperative.

Roof Preparation: What Facility Managers Should Know

When installing a roof on a commercial property, preparedness should start long before the storm clouds appear. Finding the right roofing contractor to consult on roofing materials and installation can help reduce damage, improve safety, and ease the repair process. The typical low-slope commercial roof lasts between 20 and 30 years, depending on the type of construction and materials. Maintenance also factors into the age; a well-maintained roof will last longer than a poorly maintained one.

The first consideration to take is building code compliance. In high storm-risk regions like Florida, the state follows stringent standards such as the Florida Building Code (FBC). Miami-Dade refers to Miami-Dade County, which has stricter requirements within the FBC. These standards are particularly rigorous in designated High Velocity Hurricane Zones (HVHZ), where requirements often exceed those of the International Building Code (IBC). Both the FBC and Miami-Dade protocols ensure that roofing materials and assemblies are thoroughly tested for wind uplift resistance and other critical performance metrics essential for resilience in extreme weather conditions. It is important to select a roofing manufacturer that has systems with these approvals.

Commercial Roofing Types

Roof slope and shape play a key role in how a building performs during high-wind events. Commercial roofs generally fall into two categories: low-slope and steep-slope.

Low Slope Roofs

Low-slope roofs are the most common choice for commercial buildings because they balance structural efficiency, usable rooftop space, and cost savings.

- Drainage & Membranes: These roofs require a continuous protective membrane, typically TPO, PVC, EPDM, or modified bitumen and built-up roofing, to aid with drainage and protect against the elements.

- Maintenance Needs: In hurricane-prone or high-wind areas, neglected membranes can deteriorate quickly, making routine inspections and timely repairs essential to avoid costly damage or replacement.

- Slope Specs: Low-slope roofs have a slope of 2:12 or less, meaning they rise only 2 inches for every 12 feet of horizontal run. Some designs use tapered insulation to achieve a ¼:12 minimum slope, while others incorporate the slope directly into the structure. Adequate slope ensures proper drainage, reduces standing water, and extends the roof’s service life.

Roof slope and shape play a key role in how a building performs during high-wind events. Commercial roofs generally fall into two categories: low-slope and steep-slope.

Low Slope Roofs

Low-slope roofs are the most common choice for commercial buildings because they balance structural efficiency, usable rooftop space, and cost savings.

- Drainage & Membranes: These roofs require a continuous protective membrane, typically TPO, PVC, EPDM, or modified bitumen and built-up roofing, to aid with drainage and protect against the elements.

- Maintenance Needs: In hurricane-prone or high-wind areas, neglected membranes can deteriorate quickly, making routine inspections and timely repairs essential to avoid costly damage or replacement.

- Slope Specs: Low-slope roofs have a slope of 2:12 or less, meaning they rise only 2 inches for every 12 feet of horizontal run. Some designs use tapered insulation to achieve a ¼:12 minimum slope, while others incorporate the slope directly into the structure. Adequate slope ensures proper drainage, reduces standing water, and extends the roof’s service life.

Steep-Slope Roofs

Though steep-slope designs are more common on residential properties, they are often used on commercial buildings. Steep-slope roofs, those with a pitch greater than 2:12, are a strong choice for commercial buildings seeking architectural character and enhanced drainage.

- Design & Aesthetics: Their prominent profiles allow for eye-catching rooflines, making them popular for offices, schools, churches, and retail centers. These roofs often incorporate eaves, valleys, gables, ridges, and hips.

- Material Variety: Synthetic, asphalt shingles, metal panels, clay or concrete tiles, and slate offer broad design flexibility and proven longevity.

- Wind Resistance: A pitch around 7:12 provides excellent resistance to wind uplift, while minimizing roof overhangs further reduces exposure to strong winds.

Regardless of the material or slope, proper installation is essential. Even the best roofing products can fail if not installed according to the manufacturer’s specifications and local code. Choosing a contractor trained and certified in high-wind installation techniques is key to long-term performance.

The Benefits Of Synthetic Roofing For Commercial Buildings

While a variety of roofing materials are marketed as “storm-resistant,” not all perform equally under real-world conditions. Commercial roofs are often metal or membrane-based, but these aren’t the only options. Synthetic roofing materials—engineered blends of recycled and recyclable plastics—are emerging as a preferred option for their resilience and longevity.

One of the key advantages of synthetic roofing is its combination of lightweight design and high-impact performance. Many synthetic tiles achieve Class 4 impact ratings, the highest level available under Underwriters Laboratories (UL) 2218 testing. In this test, a 2-inch steel ball is dropped from a height of 20 feet twice in the same spot, and the material must show no signs of cracking, fracturing, or splitting on the underside to pass. This level of impact resistance is particularly beneficial in areas prone to both hurricanes, where there is wind-borne debris, and where severe hailstorms occur.

Synthetic roofing also offers enhanced wind resistance, with some systems tested to withstand uplift pressures equivalent to winds exceeding 130 mph, depending on fastening methods. In comparison, standard asphalt shingles may crack, break, or detach under stress at those wind speeds as seen in Florida. Synthetic tiles offer greater performance and structural integrity under harsher conditions.

Additionally, synthetic tiles are resistant to algae growth, UV degradation, and freeze-thaw cycles. These properties reduce the risk of cracking, warping, or premature material failure, which is a common issue in coastal and humid climates. Because synthetic roofing systems are typically non-porous, they also discourage mold, algae, and insect activity that can compromise traditional roofing materials over time.

From an installation standpoint, many synthetic roofing systems are easier to handle due to their lightweight design.

Aesthetically, synthetic roof tiles are designed to mimic the shape and texture of traditional materials, such as curved clay or concrete Spanish barrel tiles, slate, or cedar shakes—styles that naturally perform well in high-wind situations when properly secured. Using a synthetic Spanish barrel maintains these benefits while eliminating the weight and structural risks associated with natural clay or concrete.

The Path To Storm-Resilient Roofing

As hurricane seasons grow more intense and unpredictable, roofing professionals must adopt a forward-thinking approach to design and material selection. Understanding local building codes, implementing best practices for installation and structural enhancements, and specifying durable, wind and impact-resistant materials are essential steps toward creating resilient buildings.

Synthetic roofing materials offer a powerful blend of performance, longevity, and resiliency, attributes that make them especially well-suited for hurricane-prone areas. While no system can eliminate storm damage entirely, thoughtful preparation and informed material choices can dramatically improve outcomes for buildings in the path of a storm.

By Brian Davis

Brian Davis is the Vice President of Technical Services at Brava Roof Tile, a premier manufacturer of synthetic shake, slate, and barrel tile roofing. With over 19 years of experience in the roofing industry, Davis began his career at GAF, where he held various technical roles, providing expertise in steep-slope residential and low-slope commercial roofing applications. Davis is an Associate Member of the American Institute of Architects (AAIA), a LEED Accredited Professional (LEED AP), and a Green Roof Professional (GRP). He holds a bachelor’s degree in architectural engineering from Alfred State University, showcasing his commitment to advancing the roofing industry through innovative and sustainable solutions.