Transform From The Edge In

Improving technologies, combined with user demands, continue the evolution of PLCs as a foundational edge platform.

Operations personnel for every production and manufacturing company have probably seen several headlines about IIoT, the possibilities associated with data analytics, and new types of edge-computing devices. It’s likely that any recently obtained assets, and possibly a lot of existing machinery, are generating useful data, if they can just tap into it. Unfortunately, few companies are positioned to add significant infrastructure and specialized programming to access that data, unless there is a clear value proposition.

There is a way to access valuable data with cost-effective edge devices and familiar software while enabling more advanced data connectivity on a scalable platform. To realize the benefits, end users should know some basics about which products and technologies are the best fit for their operation. Equipped with this knowledge, they can make the right choices for their digital-transformation journey.

Access at the edge

End users first need an effective way to access data. Industrial data is generated at the operational technology (OT) edge by instruments, controllers, and other intelligent or digital devices. Users typically need to visualize and act on this data in the information technology (IT) realm, which could be using on-site PCs/servers or cloud resources, with the latter becoming increasingly common. The data is needed for real-time reporting, enterprise and supply-chain management, and compliance recording.

Because traditional programmable logic controllers (PLCs) still shoulder much of the monitoring and control responsibility within industrial operations, they are a natural device for aggregating edge data. While PLCs have gained fantastic communications and computing capabilities in recent years, they still cannot deliver the more complete and expansive PC computing experience usually required for data handling and analytics.

However, there is a middle ground between PLC and PC, a region generally called edge computing. Some edge-computing products use industrialized hardware and ruggedized PC-type operating systems. These are capable platforms, but they often are a significant departure from PLC technologies familiar to plant personnel. Users of PC-type edge-computing systems will need the skill set to manage a PC, with its associated operating system upgrades and security update concerns. For many end users, a better option is a modern controller platform that uses customary OT functionality but incorporates IT features to better support data handling. This approach empowers staff to leverage their existing skill sets as they embark on digital-transformation projects. While some edge computing products—notably those using PC-type operating systems—can entail a higher price point and a relatively steep learning curve, there are edge-enabled PLC-based options that fit most budgets and keep things simple.

Edge-enabled PLCs

Although many PLCs today include Ethernet connectivity and support several OT and even IT protocols, there are some additional features that promote a PLC into the edge-enabled category. These include:

• Intelligent code execution options with robust task management and a variety of interrupt styles for task prioritization, ideally with the ability to accurately detect high-speed external inputs and operate to execute user code as quickly as 1 microsecond.

• Discrete, process, and multi-axis motion-control instructions to support even complex applications, executed with familiar ladder-logic programming.

• Tag-based and structured data for efficient organization.

• Powerful math functions, enabling scripted math and algebra, to support rich data pre-processing right at the edge.

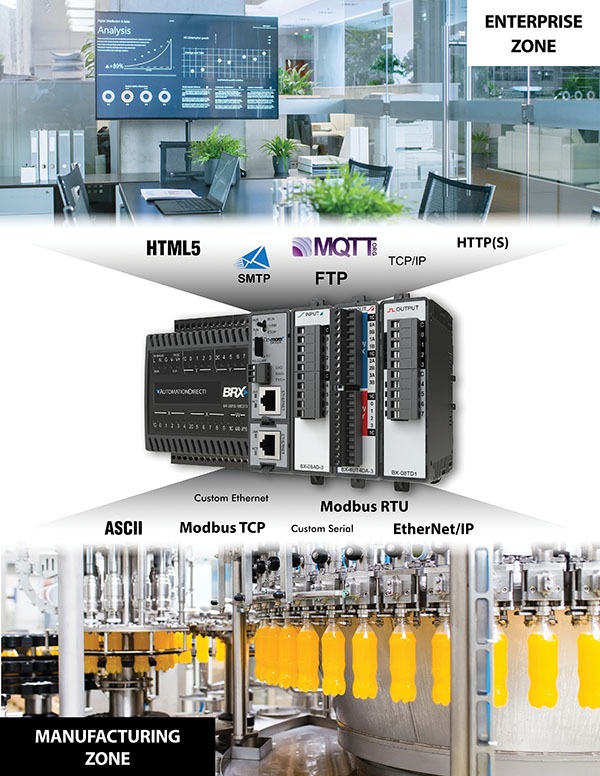

• Wide support for OT and IT communications protocols, both legacy (Modbus scanner, with no custom code required) and modern (MQTTS), to effectively bridge older technologies with cloud applications.

• IIoT features providing simplified connectivity with enterprise systems and cloud networks.

• Ability to build and host a custom web page onboard and support other external human-machine interface (HMI) and supervisory control and data acquisition (SCADA) systems.

• Support for a web API so remote resources can securely request data, such as memory addresses or tags.

• A built-in SD memory card slot and sufficient RAM so data can be processed, analyzed, and then handled using store-and-forward for transmission to supervisory resources.

The list may look like a tall order and might also seem contrary to the earlier point about keeping things simple. For a large number of end users, the most practical way of implementing digital transformation projects is to work with a familiar product and build up a solution from the very edge of their operations.

An edge-enabled PLC, such as the AutomationDirect BRX series, provides a foundation similar to a classic PLC for deterministic control and adds extensive OT and IT connectivity/protocols, analytical computation functions, and data-handling capabilities.

Empowering a PLC person

Using an edge-enabled PLC allows any “PLC person” to preserve their investments in training and experience, while opening the door to more advanced digital-transformation capabilities, without requiring them to become an IT expert. This is true for OEM machine builders and existing manufacturing and production sites.

There are a few decision points that determine when users should move from basic PLCs to edge-enabled devices. If an application requires a lot of memory or on-board data storage, complex instructions, structured tag-based data, and/or extensive data-handling with IT, an edge-enabled PLC is needed.

Some users will move to an edge-enabled PLC when they implement a new automation project or retrofit an existing control system. These users can begin by establishing the fundamental control strategies and associated logic and motion control as they always have, but with an eye toward making essential data available to higher-level systems in the future. They can add this data connectivity—using MQTTS, TCP/TIP, or other methods—at will as soon as they’re ready.

Other users will look to edge-enabled PLCs to solve field-communication problems, perhaps not even using much in the way of the available deterministic logic. For example, an edge-enabled PLC can be installed as a data-concentrator for one or more existing field devices. It’s ideal as a no-code Modbus scanner that talks with several devices and pre-processes the data to optimize results for transmission to supervisory systems.

Some field devices include Ethernet connectivity but don’t support Modbus. In those cases, an edge-enabled PLC can be used to create a custom protocol with Ethernet commands, acting as a flexible and powerful gateway, instead of requiring users to specify and uniquely configure many different specialized gateways.

Field-located hardware, ranging from sensors to process instruments, and including microcontrollers, has become increasingly intelligent and connected. The typical plant-operations team is aware of this and would like to gain some advantage from the potentially available data, but they need a practical path forward as they begin digital transformation and Industry 4.0 projects. An affordable edge-enabled industrial controller, founded in PLC basics and enhanced in the correct ways for edge data processing, is an OT/IT convergence enabler and can be the best way for many types of end users to carry out these projects. EP

By Damon Purvis, AutomationDirect

Damon Purvis is the PLC Product Manager at AutomationDirect, Cumming, GA (automationdirect.com). He has more than 22 years of industrial automation experience. Previous roles have included designing and deploying automated solutions in a variety of industries and managing product development of manufacturing data-management and business-intelligence applications.

The post "Transform From The Edge In" appeared first on Efficient Plant

0 Comments